Wearable paper pressure sensor (Credit: Neha Sakhuja)

Several industrial, automotive, and healthcare applications rely on accurate and precise measurement of pressure. Pressure sensors are used for this purpose. They detect the physical pressure and convert it into an electrical signal that is displayed as a number indicative of the magnitude.

Many applications require flexible and wearable pressure sensors. They are typically fabricated using petroleum-based polymers. But, these are non-degradable and solid waste generated from using them is harmful to the environment.

To avoid this issue, a team of researchers at the Bengaluru-based Indian Institute of Science (IISc) has now fabricated pressure sensors that use paper as the medium.

Any sensor always has a trade-off between sensitivity and dynamic range. The new sensor overcomes this problem too. According to scientists, it is highly sensitive and can also detect a wide range of pressures (0-120 kPa) with a response time of just one millisecond.

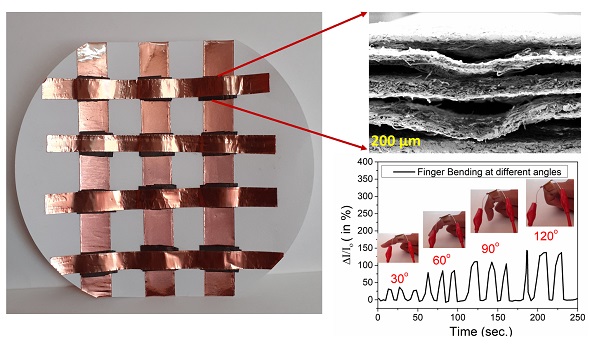

The sensor is made of plain and corrugated cellulose papers coated with the chemical tin-monosulfide (SnS), stacked alternatively to form a multi-layered architecture. Tin-monosulfide is a semiconductor that conducts electricity under specific conditions.

Several industrial, automotive, and healthcare applications rely on accurate and precise measurement of pressure. Pressure sensors are used for this purpose. They detect the physical pressure and convert it into an electrical signal that is displayed as a number indicative of the magnitude.

When pressure is applied to the sensor’s surface, the air gaps between the paper layers decrease. This increases the contact area between these layers, leading to increased electrical conductivity. On releasing the pressure, the air gaps increase again, thus decreasing the electrical conduction. This modulation of the electrical conductivity drives the sensing mechanism of the new sensor.

“The future applications of this device are limited only by our imagination,” says Navakanta Bhat, Professor at the Institute’s Centre for Nano Science and Engineering (CeNSE) and corresponding author of the research article published on the study.

As for the next step, he adds, “We would like to work on increasing the stability and durability of these sensors and possibly collaborate with industries to manufacture them in large numbers”.

“Paper in itself is an insulator. The major challenge was choosing an appropriate 3D device structure and material to give conductive properties to paper,” says Neha Sakhuja, a former PhD student at CeNSE and the first author of the paper.

The research team conducted several experiments to test the viability of their device. They mounted it onto a human cheek to investigate the motion involved in chewing. They then strapped it to an arm to monitor muscle contraction and around fingers to track their tapping. The team has also designed a numeric, foldable keypad using their sensor.

Besides Dr. Bhat and Dr. Sakhuja, the team comprised Rahul Kumar and Prateek Katare. The team has published a report on their work in the ACS Sustainable Chemistry & Engineering science journal.

India Science Wire

ISW/SP/IISc/SENSOR/20/09/2022