Ethylene is most commonly used in storing and transporting fruits. Its monitoring and control are vital to avoid accelerated ripening and subsequent loss of valuable products. Researchers from the Centre for Nanoscience and Engineering, Indian Institute of Science (IISc), Bangalore, have developed a miniaturised wafer-scale optical gas sensor, which can have widespread use in the food industry, healthcare, and other industrial applications.

Monitoring and maintaining the agriproducts is essential to maintain the quality and economic value of the product. Since they are transported in trucks and stored in facilities with limited access, a low energy-consuming compact sensor for ethylene must be used.

“Though molecular absorption spectroscopy is a widely used technique, the instruments used for such measurements are bulky. Moreover, they need multi-path interaction to achieve the desired sensitivity. In this work, we miniaturise a foot-long gas cell to a few mm thick using wafer-scale semiconductor technology. The main goal is to create an optical cavity where light and gas can effectively interact,” says Dr Shankar Kumar Selvaraja, the lead researcher.

Ethylene is most commonly used in storing and transporting fruits. Its monitoring and control are vital to avoid accelerated ripening and subsequent loss of valuable products. Researchers from the Centre for Nanoscience and Engineering, Indian Institute of Science (IISc), Bangalore, have developed a miniaturised wafer-scale optical gas sensor, which can have widespread use in the food industry, healthcare, and other industrial applications.

Optical sensing of gases offers a unique advantage, unlike other sensing technologies, such as electronic, that lack gas specificity. Optical molecular absorption sensing is intrinsically selective to chemical molecules. The mid-infrared region of the optical spectrum is called the fingerprint region. Each chemical molecule has a distinct absorption wavelength that does not overlap with each out. This allows in accurately determining a gas selectivity’s presence, absence, and quantity.

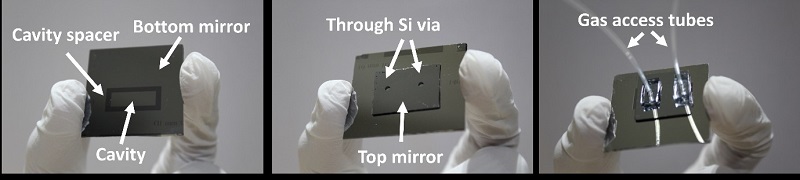

The wafer-scale optical gas sensor has a gas cell, an optical filter, and an integrated gas flow channel that can be fabricated using a semiconductor manufacturing process. The demonstrated Ethylene sensing capability of the sensor was down to 100 parts per million level.

“The sensor is made by creating high reflecting mirrors in the mid-infrared wavelength region, particularly in the 2000-500 nm wavelength range. The mirrors are made using successive deposition of optical coatings. The mirrors are then brought together with a gap that creates the optical cavity. Through holes a made on one slide of the mirror to get access to the cavity. Tubes are attached to pass gas in and out of the cavity,” explains Dr Selvaraja while speaking to India Science Wire.

The researchers hope the system can be further improved by integrating a light source and a detector. “This is a base technology demonstration; any gas and volatile products can be measured using this system. This can be used in healthcare for non-invasive breath analysis of volatile organic compounds and in giving an insight into the physiological changes in humans, Industrial emissions and process control”, the team observes.

The study has been published in Optical Sensors and Sensing Congress 2022. The team comprises Pavithra Rao, Akshay Keloth, and Shankar Kumar Selvaraja.

India Science Wire

ISW/SM/IISc/Ethylene/Eng/27/04/2023