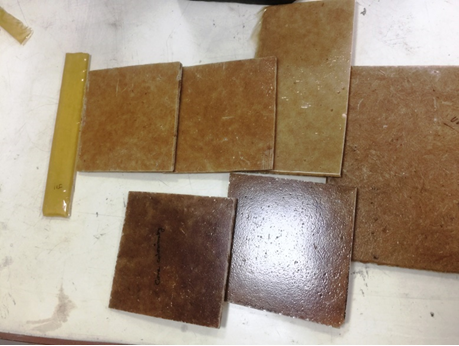

Imagine turning plastic waste into useful products likes tiles and bricks. Researchers at the Indian Institute of Technology, Roorkee, have developed a technology that will help people do just this.

All you need is polymer substance (HDPE or high density polyethylene material), some fibrous substance and a chemical developed at the Institute. People can use just about any plastic waste – old or broken plastic buckets, used pipes, bottles or mobile covers. For the fibrous substance, anything that is fibrous can be used - wheat, rice and corn straws or jute, coir, hemp fibres or even human hair.

“The technology is very simple. A person has to just heat up a mixture (up to 110 to 140 degrees) of plastic and fibrous materials in a mould with the chemical and then let it cool for some time. A nice tile or a brick would be ready for use,” said Shishir Sinha, Head of the Department of Chemical Engineering at the Institute, while speaking to India Science Wire.

" The technology is very simple. A person has to just heat up a mixture (up to 110 to 140 degrees) of plastic and fibrous materials in a mould with the chemical and then let it cool for some time. A nice tile or a brick would be ready for use "

The proprietary chemical developed by the research group is an organic chemical based on olefins. It helps bind the polymer and fibre materials to form the composites. “We have developed this chemical by using domestically available ingredients. It would cost only around Rs. 50 per 100 gram. This means people in villages will be able to produce a set of 10 one sq ft tiles at a cost of just about Rs 100.”

The technology, Dr Sinha noted, could be used with any material including waste.The research group has been focusing on using human hair as raw material for fibrous content. “Human hair has high tensile strength, is light weight and is completely bio-degradable. Products made out of hair fibre reinforced HDPE composites have been found to be highly resistant to corrosion and have good mechanical properties,” he explained.

He said he and his team focused on human hair mainly because it is one material that will be available in plenty in any villages and hamlets including those with the most poor. They just lay scattered, sometime even clogging drains and water bodies. “We wanted to ensure that at least some of the work we do could be of use to the poorest of the poor. This technology would help achieve that”. (India Science Wire)