Bone scaffolds are porous structures that are used to sustain bone grafting procedure. Biopolymers are widely used in place of metals in making bone implants. Although they are strong and lightweight, polymers lack sufficient porosity to provide a scaffold for the new bone tissue to grow on.

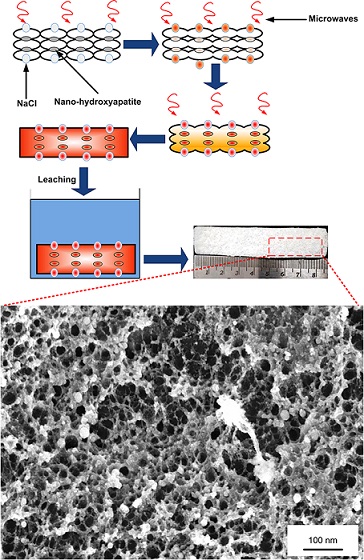

Now researchers at the Indian Institute of Technology (IIT), Mandi, have developed a novel technique to fabricate a porous nanocomposite which shows potential as a bone scaffold. They used microwave energy to fuse the polymer, nanoparticles of hydroxyapatite and salt. The salt crystals created required gaps or pores.

Preliminary laboratory tests with osteoblast (bone regrowth cells) cultures reveal that the cells readily used the pores to grow on.

“Scanning electron microscopy revealed that our processing technique yields a porosity of about 70% with pores of about 90-250 micron sizes. These pore sizes are adequate for cell growth. Also, mechanical assessment of the material revealed that our nanocomposite shows a manifold increase in tensile, flexural and hardness properties indicating its prospects as a bone implant material,” explained Dr Sunny Zafar, who led the study team, while speaking to India Science Wire.

The research team (left to right): Nishant Verma, Dr Mohammed Talha and Dr Sunny Zafar

" Scanning electron microscopy revealed that our processing technique yields a porosity of about 70% with pores of about 90-250 micron sizes. "

Researchers used a matrix material called polycaprolactone, PCL, which is a biodegradable polymer widely used in packaging, acoustics and bone-implant industries. PCL was reinforced with nanoparticles of hydroxyapatite — a chief component of bones which imparts strength to them. To this, sodium chloride or salt crystals were introduced.

All three were combined using ‘microwave-assisted composite fabrication’ technique to derive the nanocomposite. Later, the salt was removed by leaching in distilled water, leaving behind holes in the composites.

The process, according to researchers, may be cost-effective as the use of microwave for heating is rapid and will reduce manufacturing time. “We are also working to understand the physics and insights of this manufacturing process to make it adaptable for the Indian industries,” added Dr Zafar.

Besides Sunny Zafar, the team included Nishant Verma and Mohammed Talha from IIT, Mandi. The study results have been published in the journal Materials Research Express .

India Science Wire